From technology to robo-anthropology

Mark Tilden’s global journey from tech to toys to tools

This is an edited transcript of an interview we conducted via Zoom in November 2024. It follows the interview we did in 2000, published here.

Q: When we left off, you were still at Los Alamos National Labs in New Mexico.

A:

Over a century ago, feels like.

Yes almost in the last century, in fact — it was 2000.

Well at the time I was the entire robotics division at Los Alamos National Lab, which made it strange when I went to robotics conferences — there would be 50 or 60 people from other universities like MIT and Caltech. But what I did have was my working robot flea circus, always the stars of the show.

I used to tell people to beware of the “stand behind the barrier” demonstrations — you know, “Don’t touch the robot, stay back, only we can press the buttons.” Meanwhile I was passing my autonomous robots around the crowd with the power on. There were some pinched fingers, but they made an impact at the time.

My unusual approach had benefits. I was lecturing at a Japanese University once, and a co-presenter was detailing how superior their complex, AI-powered robot was. So I pushed my robot off of the table, kicked it around the stage, and it stood up and asked “What was that!”. I offered by gesture, “Okay, now yours.” I was politely escorted out of the country.

My goal was the same back then as it is today —to make robotics better. But how to do that? I always thought there must be simple, elegant ways of building competent machines. Why does nature make it seem easy, while it takes us so much effort? Look at what conventional robotics has to do just to mimic a fraction of animal abilities. Parsing automatic competence while balancing performance-to-silicon ratios to optimize power consumption and extend functional lifetimes —it’s a tricky problem for a heretical philosophy.

Since the start, my solution was “Get Real.” Given the basics of electro-mechanics, to “evolve” more able robots from primitive to complex competence, while keeping the part count low. The BEAM philosophy (Biology, Electronics, Aesthetics and Mechanics) came out of that. And I turned it into an open-source education concept for budding hackers, at a time when the Internet was barely out of diapers! But hackable electronic junk was already plentiful.

I gave it away for free for years, hoping to get others interested. I did the academic papers, TV, radio, all the Robot Olympic Games, the BEAM Robot Challenges, conferences, lectures—trying to put faces behind the robots. And what makes me feel really good is, you can go on YouTube now and look at the number of tinkerers out there, and see a good number of people who actually make money doing what we started pre-internet. It’s been industrialized—in a good way, I think.

Our hobby and profession, which is an advanced form of obsessive-compulsive disorder, led to a lot of introversion, for a long time. But now, it’s acceptable to put our robots where our mouth is. You’ll see, even today, “Look mom, I’m in the robot magazine — that’s my hand pointing at the robot.” Not enough. The robots don’t care about fame, but the humans certainly do. It’s great to see builders putting their faces next to their tech — the best protection they can offer their ideas, going forward.

So what we’ve seen in the last half-century went from Terminator-phobia — “The robots are coming!” to a brand new fear: “The robots are coming for your job!” I’m not worried — my ChatGPT prompt has sat unused for months.

Becoming Santa Claus

At Los Alamos I was spending more time in meetings and writing proposals than actually building. That drove me crazy! And NASA — holy cow! Forty-seven committees just to order nuts and bolts. Forms and presentations, bids go out for six to eight months before approvals, and all at 400 percent overheads.

For a while, under NASA’s “Faster, better, cheaper” initiative, it looked like we might be going to the stars. But politics and certain project failures (not mine) put the brakes to that. The rest is a political footnote.

In the meantime, I took one of my robots to a NASA conference, back in 1998, and put it down on the buffet table. It goes down, takes a sample of chocolate cake and brings it back to me. Meanwhile, the Purdue team is looking for an outlet to plug their robot in.

Q: So there was Solarbotics — did that start after, or while you were at Los Alamos?

That started with Dave Hyrnkiw, at the same time as the second Robot Olympic Games: 1993 at the Toronto Science Centre. Is that 30 or 40 years now (Gods)!? Solarbotics.com is still going today and has diversified significantly. It’s really encouraging—there are still communities out there, dozens of international websites, but many have spread to much more advanced pastimes, as people branched into business opportunities with new technologies.

I used to be as popular as Marge Simpson, now I’m down to, like, Maggie Simpson—or less (according to Google). But, I’ve sold more autonomous robots than anybody on the planet, I think — approximately 30 million robots since 2002 or so. A hefty army, really.

Hong Kong was an amazing town for a frustrated academic. I went there in 2000 on an invite from a guy who had his own toy trading company. One thing you could do in Hong Kong: if you had a working, viable prototype, you show it, and 30 seconds later you’re in production. How fast can you go? Compared to science, with six-month waiting times between acknowledgements, it was amazing. Factory prototypes in weeks, production in months, products on the shelves before Christmas.

Suddenly, you’re Santa Claus.

In the toy industry, many technologies and items were rejected for various reasons — they didn’t quite understand it, or it couldn’t pass safety, or required special materials, or otherwise. One of the things I had to do — if you remember the stuff I had on the wall at the Bradbury Science Museum, which looked like proof-of-concept science—was make them look like products. So the great thing that Hong Kong taught me was: How do you put a shell on something? How do you package it? How do you give it colour and style, so it looks like what it does? So someone might actually want it, and, if you’re lucky, pay for it?

It also presented a unique opportunity to inflict upon society my brand of humor. For example, the most successful robot we did — the Robosapiens — only talked in caveman burps, grunts and farts — a walking paradox of futuristic tech with a primitive mind. Exactly where I was in my progressive machine evolution. Very popular, too—even today robotics is so damn serious, and this seemed to defy that. I was lucky that toys are always good news, so I could make them funny instead of ominous.

I bought one of those — the perfect gift for a ten-year-old nephew. And I bought for myself a Bio-Bug.

Bio-Bug was the very first one we did in Hong Kong, based on the biomechs I did at Los Alamos, and years earlier at university. When you’re building something for an international market, they want to know three things: How to make it for a penny and sell it for a dime, make it available tomorrow, and no risk. Out of all my designs at the time, the basic two-motor BEAM bug design was perfect.

But the more general principle was: How to take what you have, and make it as minimal as possible, cost-wise and tech-wise? Something I resonated with immediately. While living there, I also assessed many other potential robot products—most with laptop or cell phones attached to them. That tended towards a very niche market — “cell phone not included”.

I wanted to sell things that were universal — out of the box, pop the batteries in, and play non-stop until Christmas dinner. It worked well, but it still astonishes me that inventors still believe they can sell complex-and-wonderful when the industry is always pulling for minimal-and-sufficient.

The toy industry also tends to deal with technology that is 20 years out of date—for cost, intellectual property, and accessibility reasons. Which was fine for me — I spent many years building from junk, and Hong Kong was a treasure house of previous products that were well-suited for reworking.

My years of teaching wound up being an additional bonus, because unlike many other visiting innovators and scientists, I actually went north to the factories. We’re talking about facilities more like cities. Fifteen-thousand Chinese workers in residence, for example, living on site, six per room. Assembly lines that stretched hundreds of feet, brilliantly set up. One person on one side does the thing, and someone on the other side tests it. Then they play musical chairs until parts-in equal product-out at maximum efficiency. That’s called “convergence toward product”. It takes less than five days, even for complex items, and it was amazing to watch, and to supervise.

I asked one of my factory floor managers, “Who invented this amazingly efficient production process?” And he said, “Ah, yes. Emperor Qin Shi Huang. 300 B.C.” Okay! Can’t argue with tradition.

My experiences were incredible. The first time I went to a largish toy factory in Dongguan, they awkwardly stood me on a table, brought out around 20,000 employees, and they all sang me the company song—all wearing identical uniforms of blue pants, pink work-shirts, white head scarfs. And all waving their hands high. And I realized, “Wow, all these people are here to help me push plastic into Santa’s bag.”

I never approved of Mao Tse Tung, but having been there, I get it! Remember, I came from Los Alamos, where I was literally a one-man band. And now here, all these people depended on what I was able to provide.

And it seemed true enough. The head of one of China’s largest toy companies told me, “We must depend on people like you to innovate. Because if you don’t, then I must go and buy a Rolex watch to imitate.” He’s got kids and employees to feed, and if he doesn’t come up with new products, he’s got to go and do something less than honorable, to keep the machine running.

Nice to know I was vital to the process, but there were frustrations as well.

Chinese manufacturing culture is such that, we would have our assembly line here, and there would be another one right next to it, building knock-offs. I questioned this, and was told, “Would you punish your mother for feeding your brother?” A frustrating work ethic, but since their end goal was to maximize employment on their end, it made a certain sense back in the early 2000’s.

Crossing the border from Hong Kong into mainland China, it really is like night and day regarding the rash of reason. I remember a poster on a wall that said something like, “This is an ISO 5000 compliant situation. People must be at least 18 years old” — crossed out, “17 years old” — crossed out — “14 years old” — crossed out — “to work here.” A certain business flexibility was necessary if you were to move projects forward.

Robots everywhere

So we came up with Bio-Bugs, based on all that technology that you saw back in 2000. And we came up with a fantastic ad campaign that premiered during the Star Trek Discovery TV show, with Bio-Bugs walking across a hellish city landscape.

Then, two months later, 9/11 happened. And all my media interview questions changed for the worst.

When you’re a scientist, you have to be very serious, talking about how beneficial robots are, etcetera. But when you’re talking about toys, it’s supposed to be good news, happy news! The name Bio-Bugs was a little too close to “bio-warfare”, and interviewers were quick to bring it up, thereby bringing the whole tone down. We’d chosen the names and the marketing style way before, but we were suddenly accused of supporting terrorists somehow.

My bosses and agencies left me to talk to CNN. But I kept on-message, and we still moved several million Bugs that year. Not bad for a first go.

When you and I last met in 2000, I had done some crude bug designs. But in Hong Kong, I was quickly moving up, through quadrapeds (dogs, cats, etc.), soon to humanoids, and even more sophisticated morphologies. I also wound up personally selling and promoting them internationally — living in airports for almost four years — the first world travelling robot evangelist. Hallelujah.

RoboSapiens looks very gorilla-like, if you look at the overall shape of it — it was exactly one-fifth my size proportionally, with seven motors.

A few years later we did FemiSapien, which was as close to a properly proportioned humanoid as I ever built — the same principles, but more advanced with only five motors, and a better Reduced Instruction Set Controller, for all her personable actions. Mechanically sophisticated, with a brain designed to spec.

Worked well, good price, I was quite proud. But massive controversy: “Who are you building this for?”

Over the years, many had asked when I was going to build something for girls. I’ve met a good number of female tech-types, and asked what they would have liked growing up. We stuffed her with sounds and secrets hoping to turn her into an internet diva. The way you programmed her was to move her arms and legs like an animated character, recording her actions to play back later. It made sense—they need to be trained, but in an easier way than conventional programming.

She did very well, especially in Japan—despite CNN asking all kinds of awkward questions. She has a huge number of hidden features, and made several appearances in music videos, TV shows, movies, etc. Again, the creations becoming more famous than their inventor! As it should be.

From Nervous Net to record-and-play

Fun fact: After you sell your first several million robots, people will come to you and ask things like, “We have a Taiwanese silicon manufacturing factory. Do you have any ideas for a microcontroller you might want for your toys?” What a coincidence! As it turned out, I had many ideas! And I foresaw more exotic behaviours. And I saw the marketing advantage of reducing the cost of a robot brain from five bucks to twenty-five cents each.

So I was able to realize my crazy ideas, by literally designing my robots from the ground up, at a reasonable cost, while also advancing my original evolutionary premise. Plus, I was advancing from technology to anthropology. I could go down to Toys ‘R’ Us and say, “You — drop that teddy bear! Buy this robot instead!” All the while knowing I was helping promote robot culture for the 21st century. At least, that’s what I told myself.

Tell me about the intelligence that went into the first Bio-Bugs.

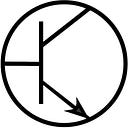

“Nervous Networks” I called it. Primarily, adaptive Central Pattern Generator oscillators using handfuls of transistors with direct control over drive motors. Best performance-to-silicon I could manage at the time. Still pretty tight!

The problem was, we couldn’t use analog controllers for commercial toys, because we needed sound output and production stability. So we were forced to use conventional music playback Micro Controller Unit (MCU) chips popular in the 1990s. My Nervous Net systems generated patterns that the MCU chips would “record” just like playable sound sequences. And that’s how the first robots worked.

In Bio-Bugs, we used an off-the-shelf toy microcontroller, programmed to the last available bit, but the original brains were Nervous Net analog control technology. I got very good at duplicating most microcontroller functions with Nervous Net, quickly and cheaply.

I’ve got Nervous Net robo-lego all over my desk right now — it has all the pieces you need. There — that’s brains right there. Less than five cents each, and they’re completely disposable, so you can mount them into a chassis forever, without worry.

Initially I saw in Hong Kong that you build something that functions, then it disappears into China. And guess what? They might have no idea how it works. But they can duplicate it to their best.

But with this, they completely failed. If it had been software, they would’ve had no problem duplicating it—they have an infinite number of programmers. But I gave them a big pile of adaptive analog instead.

So we came up with a technique that was really quite fascinating. They would put my prototypes onto this incredible table with the best digital samplers and scanners. And they repeat and record the patterns the robots make using a drum machine!

So all the things that Bio-Bug does is not some sort of AI. It’s an analog pattern, recorded into digital on a drum machine. And then reproduced, because they couldn’t do it in digital. That was the best compromise we could get, so that they could duplicate it. Even still, the results were pretty Frankenstein.

So, the best possible way to protect your technology? Well, I tried to explain Nervous Net systems to them, but they didn’t want to know. They only wanted to know, “What is the fastest way we can get it to work?” And for business reasons, that’s exactly right. I had to get out of the academic mindset, and think about what it would take to advance the project forward.

See, the main thing about dealing with toys, and something that I really loved, was two rules: First, Santa Claus don’t wait. December 25th — miss it and you’re dead. For this reason, I was more than willing to go all the way to the factory and nap and smoke with the workers. Right there to solve engineering problems as they arose.

Lessons from Santa

But that caused problems itself. Once I walked up to an assembly line, while they were building one of my polar bears. I leaned over, frightening this poor worker, and she cut off the nose of the polar bear and burst into tears! The whole assembly line had to stop because I had scared the crap out of her. I was much more respectful from then on. Live and learn.

Problems came from the weirdest directions. And sometimes they were fatal to the project no matter how far along development was. There were many things that we put tons of time into, and then, just before shipping, somebody came along and said, “You can’t do that,” for various legal, safety, sometimes cultural reasons.

Have you ever wondered, for example, why there is no such thing as a high-jumping robot frog? A toy frog? The thing is, any such design puts out an awful lot of force, that could damage a young child’s eye for example. Banned for all the right reasons.

There are about 3000 rules a product has to satisfy before it can appear underneath your Christmas tree. Little things like, if it’s run over by a car, the shattered parts can’t be sharp enough to hurt the innards of a dog who might eat it. Drop tests and pinch tests — 1.2 cm is the minimum distance you can have. You can rub something, but you can’t crush something. On and on.

These are the things that you learn working for Santa Claus.

The second rule, though, is: Santa Claus is a bastard. A lot of people come up with one idea and go to Hong Kong, and their idea is rejected for a variety of reasons. You have to apply a shotgun approach to products. I had dozens of working robots, but only Bio-Bugs ticked all the boxes that first year.

So with Bio-Bugs, despite the downturn in the market after 9/11, they were fairly successful, astonishingly. I went from the back room to the sales floor fairly quickly—thanks to my father, who taught me how to sell anything.

How long were you there?

Sixteen years. Some of me is still there today. [Details below]

As a result, I was finally able to do something I wanted to do for a long time. Which was to take 50 of my robots out to White Sands, New Mexico for an autonomous wander. It’s an absolutely surreal place. The sand is so white — it’s pure gypsum — that it doesn’t heat up. So you can put down plastic robots and they won’t melt.

I’d always wanted to find out what would happen with a group of Bio-Bugs together — what properties might emerge? A lot of people don’t realize how much variation was in them. There were four versions that I evolved, over many years. But you couldn’t really see everything they were capable of, because — let’s face it — living rooms are too small!

So we were out in White Sands with the Discovery Channel. We went out with 50 of them, and we came back with 42. So, out there, somewhere, there are eight bugs still going. They would walk down a bank, and get completely covered in sand. And I said, “Okay, that’s one for the desert!” But other ones followed each other’s paths and patterns — you could see their footprints in the sand.

So I was still doing science, proving to myself that these things could survive, to see how they worked, so I could feed that into the next generation.

After that, we did a variety of dogs, aliens, and some other animals. And then there was RoboSapien. You know that old joke about Marconi: He wouldn’t have discovered radio if he hadn’t, completely and by accident, been thinking about it for 40 years? So I had been thinking about minimal humanoids for a long time. And then I literally built the first RoboSapiens in a month, at a science conference, while everyone was watching. On the last day, I powered it on, and it sprinted across the table.

The thing people don’t realize: It’s a 13-inch high, two-kilogram robot that runs for 24 hours on a single set of batteries. Try doing that with anything that involves servo motors. Most any other toy that you get on Christmas morning, first you have to charge it, and then it runs for maybe fifteen minutes .

With RoboSapien, every step it takes, 75 percent of the power is regenerated back, using the battery as a superficial capacitor. That’s also the reason it was so fast and fluid — because it’s actively generating power as it walks.

It’s a principle I was working on for a long time — a form of reflex electromechanics different from the typical setpoint-controller-servo system. I thought, “What would happen if there was a natural resonant center to an entire elastic structure?” Like if you let your wrist go limp, your hand will default to a certain position. Apply that to a whole body, and that’s exactly RoboSapien: it’s one-fifth my size, and by default shaped to my proportions—as if I’m floating in a pool.

Everything is held together by springs and pivot points—no servos. That helps to regenerate the power back to the battery. And it works so well that the robot has a massive battery life with regular batteries. Even today, quite impressive I think.

Nobody has found all the Easter eggs in it — I loaded it with secrets. You could teach courses in operant conditioning and subsumption architecture. The little gearboxes we built are now an industry staple. If you’ve ever taken apart a robotic toy and all the gears fell out, well now you can take one apart and you’ll find one of my modules — a completely self-contained gearbox, with a slip clutch and the appropriate motor in it. It’s standard, like an infrared detector — we sold millions and millions of units. And it’s still one of the biggest sellers at Solarbotics.

There are so many wonderful stories about RoboSapiens. For the first time, I was able to see true, interactive robo-anthropology. There’s that crazy guy in Scotland who had 20 RoboSapiens pull him down the street on a skateboard. Other people treated it as a little actor. Because actually, I hoped it would help the camera-shy, by being their little avatar. And it worked like a charm. There are hundreds of RoboSapiens videos floating around the internet, even today.

Most toys have a five percent return rate — five percent of them are returned to the store. RoboSapiens had less than a one percent return rate. And they showed up everywhere. When I watch TV, or YouTube, I always see them on a shelf in the background. The Big Bang Theory, for example — one was there for the entire run of the show. In various Hollywood movies. And there’s more than one Doctor Who episode with my dinosaurs kicking around the background.

How long did it sell for?

Right up until the pandemic, so about 15 years. I think we sold 12 million in total.

But, my bosses noted that we didn’t do anything to protect the technology from knock-offs. Meaning, I’ve got an entire box of crude RoboSapiens knock-offs by other manufacturers. However, if you don’t understand the technology, you reproduce it in unusual ways. They put wheels and lifts on legs—not true walkers at all. Without the Nervous Network as a starter backbone, it seems they had a hard time.

So the best way I learned to protect our intellectual property is: You’ve got a 90-day window between September when you ship, and Christmas. After that, you just let it go, because your best defense to preserve future markets is a sequel.

My bosses came to me and asked, “Can you make a robot that can see, and do it for less than a penny. Also, we’ll need voice recognition—for all languages on the planet.” I looked at them, eyebrows raised. and said, “OK, I can do that! Want me to do something about the speed of light while I’m at it?!?”

Fortunately I had minimal solutions for just about everything. It’s just a matter of re-creating it with local toy-grade parts.

Are you familiar with the Exposure Paradox? When you realize you can do everything, you tend to sit there in the dark and do nothing. But, if you go to a place like Hong Kong, you’ve got all these people saying, “Whatever you give us, we’ll put it on the shelf.” This can focus you effectively.

It was so cool to be used to full capacity like that. But every day was madness.

For example, one of our salespeople came and said, “Dinosaurs.” Now, why are robots and dinosaurs some of the biggest staples among all toys? Because one is so far in the future that you’ll never see it, and the other is so far in the past that you’ll never see it. So why don’t we combine the two?

I went back to an academic paper I wrote around 1992, which talked about the potential resonant structures of a Tyrannosaurus rex — a bipedal dinosaur. They said, “Okay, how big do you want it?” And I said, “Size of box equals size of daddy’s love.” So we made the things a meter long! And we sold over eight million.

And these things really ran, on just six AA batteries. They would run from Christmas right up until it’s time to go back to school in January. We took what we learned from RoboSapiens and applied it across a wide range of items.

I have a great memory of being chased down a factory hallway by 300 of these dinosaurs, and me with the only remote control that could stop them. Noisy, and actually scary as f*ck!

At the same time, we did the RoboSapiens 2, which was a giant robot: RoboSapiens, but almost twice as high. We gave it a camera, ears, flexibility. Japan was doing a variety of semi-humanoid things at the time, but they were all unavailable, unassailable. RS2 was the first robot large enough to have human-sized hands. It could pick up real things. So of course we had to limit the strength, for safety.

But, how do you make a two-foot-tall robot that could power itself, but not enough power to actually hurt somebody? And again, it had to run on regular batteries for hours.

My bosses were constantly pushing to come up with new products. I came up with a series of robots that were aliens, based on my old Mars rover research. Fun fact: it turns out that Martians never pay for any of the robots we send them. Human parents—different story.

I recommend going to YouTube and searching for “puppy vs. robot”. It’s one of my spider robots up against a brand new puppy some lost Christmas morning. Funny as hell. One of hundreds of similar posts.

At the time, it was interesting to see YouTube emerge over television not just as a place for advertising, but as a destination for toys — a place to play with them in public, as performance. And for us, as the manufacturer, we got direct evidence of how customers were interfacing with our products.

The Uncanny Valley

Even with analog signals recorded into digital, my robots still seem to have an aliveness that animals respond to. If you’ve ever tried to run over your dog or cat with a radio-controlled car, many won’t even look. But back in my Los Alamos days, my giant spiders were never accepted by my friend’s huskies—violently so. And that’s something we tried to keep intact through the subsequent generations of production products.

Think about the Uncanny Valley. How did it come about that we’re so afraid of something that looks just like us, but not quite? Where in our evolutionary past was there something like that? You gotta wonder, when will the robots cross that boundary?

For me, it’s a bit like dealing with farm animals. As long as you’re smarter than they are, be sure you’re the one holding the reins.

Next, I wanted to build an intelligent lamp, called Roboboa. We did well with toys, and someone asked me, “When are you gonna build something that’s actually useful?” So I thought, What would every college student want on their side table?

You remember those animated Pixar lamps? Just like that. Something that didn’t just help you see, but could itself see. My boss came to me and said, “We need something that can detect a human being two to three meters away. And it’s got to cost 15 cents.” No worries boss!

We wanted to sell it not just at Toys ‘R’ Us, but at places like Sears Roebuck, meant for your toolbox. It was a flashlight that followed your hands around — you didn’t need someone to hold the flashlight for you. You could talk to it. Very much like the helping robot hands from the first Iron Man film.

But, once again, a really nasty reality came about: You cannot sell toys in the tool aisle. The way our economy is set up, there are toy buyers and there are tool buyers, and never the twain shall meet. Again, a stopgap out of nowhere.

So we reluctantly packaged it as a toy and moved many, but I’m the only person I know of who used them as desk lamps. Pity.

Robo-stories

In the meantime, our robots were gaining momentum in some diverse public forums — I pushed our surplus stock out to pretty much anyone who would ask, just to see.

Boston Science Museum, for example, asked if we could offer robots to rotating groups of visiting students. We gave them 100 robots, and they played with them for six months before they started to break beyond repair. Six months of nonstop child play. Brutal.

We got some of the worst of them back, just to assess the failure points, and the triage was horrific: “How did they get gum on the processor?!” These things were pushed to the absolute limit. Forget Mars—here was the real robot battleground.

We gave a large number of RS2’s to a crippled children’s hospice in L.A.— kids who are trapped in their beds for Christmas. They couldn’t get out, could barely move, but they could use a remote control.

And they found ways to get the robot to bring them things, to open a refrigerator, retrieve books, untangle hoses. I was amazed. They had the time and effort to skill-up the robot just like a video game, finding ways around the inhibitors to do useful work. Astonishing to see. Encouraging to hear.

When we went back the next year to ask if they needed more robots, they still had the ones we gave them, but unfortunately the kids were gone. Nobody in hospital wants to play with a dead child’s toy. So they were chucked. In a way, the robots died with the children. I always wondered if they were ever a help or just a distraction, but we never received any letters telling us one way or another. Granted, hospitals are busy places—from my own experience.

Sometimes we did get letters though.

After Hurricane Katrina, we got a letter saying, “We went back to our house, and there was a RoboSapien caught in the only tree on our property. And it was really valuable because it was the last gift that grandfather gave to our son before he disappeared. Can you fix it?”

I opened it up and ran it through the dishwasher to get the mud out. It booted right up after drying. I sent them back the original, and a brand new one in a box, with a nice letter from Santa.

For moments like this—just for a moment—I was Santa.

And there were many similar stories, some of which are still viewable on the internet, over 25 years. Robotics is usually a sterile field, full of mildly dry, engineering anecdotes. But sometimes, sometimes…. A lot of people pooh-poohed me for going from academia to toys, but occasionally we actually touched people in ways never expected.

Fascinating. Bizarre. Exotic. Important. I think.

Inside the lab

Since then I have increased in sophistication, and scaled up. Here — check this out.

Q: That looks almost life size.

Five foot nine. Hopefully to retail for about $1000. Again, all based on reflex mechanics and Nervous Net control. But also, cameras in her hands — so she doesn’t need anything in her head. Runs on batteries for hundreds of hours. Still a work in progress, as I work out the nature of her sensor systems.

So, again, an attempt to transition from toys to tools — a realistic interface for experimentation. Or, imagine a kind of remote shopping experience: you’re at home, the robot is in Singapore, you control it with your phone or tablet while it wanders a distant mall robo-shopping for you.

There’s also robo-tourism. Where could you go if you were a fairly disposable robot? What resorts wouldn’t offer a virtual guest service? A bit more sophistication and you have a robot executive assistant or stenographer.

These are all applications we can do right now, that people will pay for, and within the dignity of the technology. I’ve always thought that getting a high-priced robot to wash your car is like getting Michealangelo to paint your fence. Right tool for the right job.

A harsh lesson from Mother Nature.

So Hong Kong was great. I put in 18-hour days, and at night, with all those lights, in the rain, add a Vangelis soundtrack and it was Blade Runner. Considering my profession — appropriate.

Q: So what happened? You said the Communists set fire to your office.

Something even worse happened. In 2015, I went on holiday in Florida, and stepped on a jellyfish on the beach.

Oooh, that’s worse.

Yes, it was. An MRSA superbug slowly ate my foot from the inside out. I spent a year in a Chinese hospital. Pretty much the end of my career, and my left leg.

Also, having sepsis does a number on your head. But my then-girlfriend (now wife) did an amazing thing — quit her job and came all the way to Hong Kong from Canada to get me out of there. I came back, and I was pretty much forced into… an easier lifestyle.

At the time, I was doing a lot of work at the Hong Kong Polytech, which was right next door to where I was working. Some colleagues (Ben Goetzel, David Hanson, et al) at the time were building a deterministic AI robotics model, which I think should be pursued further — that’s where the system will give you the same precise answer again and again. As compared to the many stochastic language models now in development.

Think of the computer on the Starship Enterprise. It always said the same response (with Majel Roddenberry’s voice). Always extremely predictable — because this is what we want in our tools!

See, something like ChatGPT is a language model, and language is not precise. Are you going to trust a business decision on a ChatGPT maybe-response and possible hallucination? Someone needs to build a ChatGPT scientist, or engineer: the most annoying, pedantic academic you can imagine. That would actually be useful, because it would force some humans to recognize that precision and complexity are vital when you’re poking the edge of physics.

Go back to Iron Man. Like the computers from Star Trek, a robot like that needs to be much smarter than—but willing to compromise for—its human contemporaries.

We were getting very close to a lot of that over 10 years ago. Then a jellyfish reminded me of its superiority in the evolutionary hierarchy. Little shithead. Glad it’s dead.

Robo-evolution

So I started a long healing process back in Canada. First to walk. Second, to get my brain back. And recently, to start building again.

In the current business of robotics, people are still pursuing what I call steam robot technology. I’m really impressed with a lot of the robots out there, but the fact is, they’re still pushing a complexity barrier I think has a dead stop at the end of it. Very few can pass a pull test, a drop test, a pinch test. And because of legitimate safety concerns, we couldn’t let them near our children or pets.

When you change your world and your behaviour just to suit the robots, they’ve won. But—they haven’t. Because we wont put up with that crap. It’ll be a fad, then it’ll be surplus.

It’ll be interesting to see what happens next, now that plagiaristic language models seem to be hitting a plateau. They’re not the killer app the companies were hoping for. I’m pretty sure I’m not the only one yelling into a phone, “Representative! Give me a human!”

Also, try to get ChatGPT to understand a thick Scottish accent.

Have a look at this. This is a robot mama…

What is that? It looks like Hal.

It’s a voice-controlled robotic sequencer and bench supply of my own design. I can hook it up to my Nervous Net arrays over there. Or to robotic tools — like prototype equipment that has sensors and motors. I can activate it with a voice command. Very handy if your hands are full.

In the evolution of robotic tools, how much intelligence do you want to give your drill? Not much. But, if you’re doing what I do, it’s useful to have a voice-controlled lab assistant with a little more.

All the brains I put into my robots are completely modular. So you can take the brain out of one and put it into another. What can you put inside a tool that isn’t a gimmick, but something that’ll actually help you when you need it?

My wife asks, “When will that robot in the backyard be big enough to push a broom?” And when I think about it, that’s exactly what it should be doing.

It’ll be interesting to see what happens as the tech scales up — completely automated factories and all that. You’ve got a few fully automated grocery stores there, in London. But what happens when they fire all those minimum wage workers, then spend a fortune on the tech, and need highly-paid programmers just to maintain and service the damn thing. And how long can it last if it’s just a cosmic ray away from catastrophe?

Plus, if you go into a completely automated McDonald’s, it’s even worse than soulless. For some reason, my voice is an in-between register that no robot recognizes. “NO. I. WANT. IT. WITH. NO. CHEESE.”

Instead of my car telling me, “You’re too drunk to drive,” I’d rather hear, “You’re too drunk to drive, so I will drive you home.”

Post-Hong Kong

So, to finish my story, I flew back to Canada in 2017, they amputated my leg, and I’m now partly robotic myself. Which is maybe ironically appropriate. But damn annoying — phantom pains have me believing in ghosts again (By the way, the answer for me was Tumeric, but it took years of experimentation.)

I wanted to get back to Hong Kong, but I worry I might be on a list.

Aha.

Yeah. At my Polytech, I have some pictures off of CNN — of my office on fire. Of the 28 people in our group, I know of only three who made it out for sure. Not sure what happened to the others. Hope they’re ok.

Hong Kong in the 2000’s was a dream. After the handover from the UK to China in 1997, everyone thought it would become like Vancouver with noodles. Alas.

So now, I’m trying to start a robotics effort here in Canada. And I’ll keep building things, carrying on with the evolution towards useful tools, like I always have.

The bad thing about Hong Kong was the waste — the culture there is very “new or nothing”. They throw away absolutely everything. Once we had 200 RS2’s walking off the roof of a building because they were all slightly defective and couldn’t be sold.

So the one thing I was able to do when I left Hong Kong was to take all the junk I could from my labs and factories, which I cannibalize for parts even today.

The thing is, if you build toys, you’re a low-grade entertainer. So now I’m building tools. What kind of thing would people immediately recognize as a useful and valuable robot assistant? I’m testing items right now that I think might actually do significant jobs. My voice-controlled lab assistant is one example.

Obsolete tech has so much available potential. For example, there’s an amazing toy, worth looking up, called the Hansen 20Q. It’s a little box that guesses what you’re thinking in less than 20 questions. It’s from 1988! That was based on an incredible study by a British professor, who came up with a statistical model based on a range of English-language databases. Worked well, dead cheap, obsolete technology, no risk… Hey, that sounds familiar!

It was just a database, but if you gave that thing decent speed, sensors, and a body… No matter what you do with AI, it’s always gonna be a brain on the other side of the glass. If you want it to be marketable, give it legs.

What do you think of the current raft of humanoids being promised?

Well, it’s early days, but too heavy, too expensive, too complex, and far too dangerous. If you were able to market a robot Brittney Spears, you couldn’t sell it to the public because it has nineteen pinch points, seven crush points, and six finger traps. Animals can get away with it because we’re mostly soft and we run on readily available proteins. Hard-shelled, full-scale machines are a significant danger, from my personal experience. The first time one is Tik-Toked falling on a house pet, game over.

That means they have to sell to businesses only. But to make a robot pay, it has to put in a 40 hour work week on a single charge. And work flawlessly for at least two years without maintenance. Even mature technologies would be hard pressed to meet such specs. And the cost is outrageous.

The thousands of safety rules established years ago for the toy and product industries are not just for laughs, but carefully evolved to meet the public’s casual needs. Robotics companies need to consider these, or we’re unlikely to ever see anything more exotic than a Roomba.

Any advice for budding roboticists?

Yes. On all beaches, alway wear watersocks.

But also, whatever you make, personally or professionally, choose methods that allow you to build faster than your speed of distraction. And be sure to finish your projects as existence proofs, because nothing is more powerful than repeatable physics that works.

Hey, I got this in a fortune cookie in Hong Kong:

We’ll see about that.

From my experience, minimal competent machines are possible, marketable, and essential for the future of humanity. But only if they are good news.

Q: I met someone from Google DeepMind recently, who believes that AI won’t get much further unless it merges with robotics. Because computers need an embodied knowledge of the world.

Is that person’s name Alan Turing? Because that’s what he said about 70 years ago!

The cost of AGI [Artificial General Intelligence] has two things against it. One is the cost of the robot itself — minimum $100,000 for something that is barely operational, and might last 40 minutes on a charge. The other problem is capacity. Do you know how big a ChatGPT brain is? It’s football stadiums! “Shall we add more compute?” No! you’ll just make it more confused.

By contrast, you can build a nervous network brain like the ones I do, with as little as six nodes. And it learns: if you treat it shitty, it’ll learn to be afraid of humans. Treat it well and it’ll follow you around the room. What is the smallest network that’ll result in animal-fast predictive actions? Because that’s what you want in a robot tool.

So, deterministic behaviour, afferents, and emergent properties. Then you get machines that do things that are more than expected. And then, how do you improve that, so it goes beyond just survival to utilitarian behaviours?

I hope there are still scientists out there who are pursuing minimalistic models like this: simple, elegant ways of doing things. Because (a) that’s the only way we’ll be able to afford them, and (b) it’s the only way to converge on solutions that we can deploy in the field. You don’t want robots fighting your wars who go out there and then have an existential crisis. Or hallucinate. The best tool is the simplest tool.

Bonus content! Mark sends the following schematic, for all the engineers out there. If you have insights, Mark Tilden needs you in his secret Canadian lab…